- +86 20 3114 7096

- [email protected]

- Mon. - Sat. 9AM - 6PM

Elevate your commercial and industrial spaces with high-performance tent air conditioning – the key to optimal comfort and productivity in any environment.

Get a QuoteExperience ultimate camping comfort with Drez portable air conditioner, ensuring a cool retreat wherever your adventure takes you.

Get a QuoteTransform exhibition spaces into cool havens of success with Exhibition Tent Air Conditioner – redefining comfort and creating the perfect atmosphere for showcasing excellence.

Get a QuoteUse our advanced cooling solution to improve the efficiency and storage of the production workshop.

Get a Quote

A structure specifically designed for tents, which can be applied to standard or other special tents.

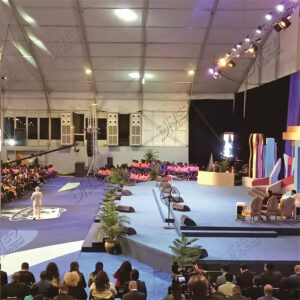

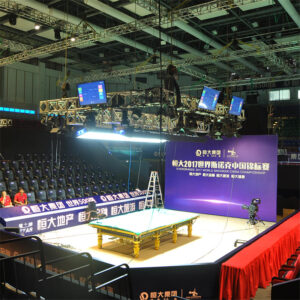

Specialized cooling solutions for events and exhibitions. Our systems are crafted to create a pleasant atmosphere in large venues, ensuring attendees stay cool and engaged.

it's the essence of our commitment to excellence in air conditioner products and services. We tailor every aspect of our offerings to enhance your comfort, whether it's through innovative air conditioning solutions, personalized service, or cutting-edge technology.

Is not only suitable for tents but also provides powerful cooling performance for facilities like factories and exhibitions.

Identify core requires

Every activity has specific control requirements vary with environment, place and many factors. Every client wants to hose an unique party. We will identify core requires with you at beginning.

Planning

Drez has good team to realize client dreams, from blueprint to insight step by step. Innovative latest HVAC tech is used.

Implementation

Drez has more than 50 different models, from 3ton to 50ton. Air-con operates within -20~55 degrees. Stablity and reliability is the promise.

Results

Drez provides free warranty, 24hr service and life-time technical support.

We have more client or friend globally.

We know how it works!

If the plan doesn’t work–change or update the plan, not the goal.

Human has an infinite demand to climate control. Drez has been trying best to satisfy the climate control demand in a variety of temporary activities or building, through thousands of successful projects.

Your demand is Drez’s goal, We know how it works!